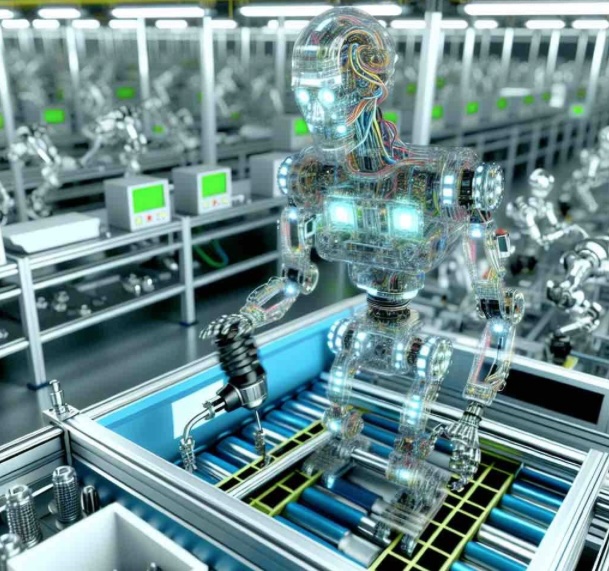

As Artificial Intelligence becomes more prevalent, one use case being seen is in product manufacturing. Artificial intelligence (AI) is revolutionizing the manufacturing industry, offering numerous benefits to companies. Here are some of the key ways AI is assisting manufacturing companies:

1. Predictive Maintenance: AI algorithms analyze sensor data from machines to predict potential failures. This proactive approach minimizes downtime, reduces maintenance costs, and improves overall equipment efficiency.

2. Quality Control: AI-powered vision systems can detect defects and anomalies in products with high accuracy. This ensures product quality, reduces waste, and enhances customer satisfaction.

3. Supply Chain Optimization: AI can optimize supply chain operations by analyzing historical data and predicting future demand. Most manufacturers are using Just In Time (JIT) inventory, so this helps in efficient inventory management, streamlined logistics, and cost reduction.

4. Robotic Process Automation (RPA): AI-powered robots can automate repetitive tasks, such as assembly, packaging, and material handling. This increases productivity, reduces labor costs, and improves accuracy.

5. Design Optimization: AI algorithms can analyze design parameters and suggest improvements to optimize product performance and reduce manufacturing costs. This leads to innovative product designs and faster time-to-market.

6. Energy Efficiency: AI can monitor energy consumption patterns and identify areas for improvement. This helps in reducing energy costs and minimizing the environmental impact.

7. Worker Safety: AI-powered systems can monitor worker behavior and identify potential safety hazards. This promotes a safer work environment and reduces accidents.

8. Predictive Maintenance: AI algorithms analyze sensor data from machines to predict potential failures. This proactive approach minimizes downtime, reduces maintenance costs, and improves overall equipment efficiency.

9. Quality Control: AI-powered vision systems can detect defects and anomalies in products with high accuracy. This ensures product quality, reduces waste, and enhances customer satisfaction.

10. Supply Chain Optimization: AI can optimize supply chain operations by analyzing historical data and predicting future demand. This helps in efficient inventory management, streamlined logistics, and cost reduction.

11. Robotic Process Automation (RPA): AI-powered robots can automate repetitive tasks, such as assembly, packaging, and material handling. This increases productivity, reduces labor costs, and improves accuracy.

12. Design Optimization: AI algorithms can analyze design parameters and suggest improvements to optimize product performance and reduce manufacturing costs. This leads to innovative product designs and faster time-to-market.

13. Energy Efficiency: AI can monitor energy consumption patterns and identify areas for improvement. This helps in reducing energy costs and minimizing the environmental impact.

14. Worker Safety: This is a fairly important item, as workers compensation costs have gone up. AI-powered systems can monitor worker behavior and identify potential safety hazards. This promotes a safer work environment and reduces accidents.

By embracing AI, manufacturing companies can gain a competitive edge, improve efficiency, reduce costs, and enhance product quality. It’s a powerful tool that is reshaping the future of manufacturing.